|

Boeing 787 Dreamliner Updates on Battery Issue

|

||||||||||||||

|

|

||||||||||||||

|

Boeing completes certification testing for new 787 battery system

The world Industry experts disagree on consequences of the grounding: Airline companies are confident even Airbus is confident that Boeing will resolve the issue and that no airlines will switch plane type, while other experts see the problem as "costly" and "could take upwards of a year Even if in the mist of the world focused battery incident for 787 Dreamliner, you can see the bonding and working together to resove the best as human can be throughout the world, Government agencies, Boeing and customers, partners, suppliers, agencies,communities are helping each other for the best result and anxious to see the Boeing 787 Dreamliner to fly safe. Many Airline companies and industries, the suppliers and partners, including the tax payers, communities are anxious to see the Boeing 787 Dreamliner to fly soon which there is no doubt that FAA will soon certify the 787 to fly with safe and peacefully...........

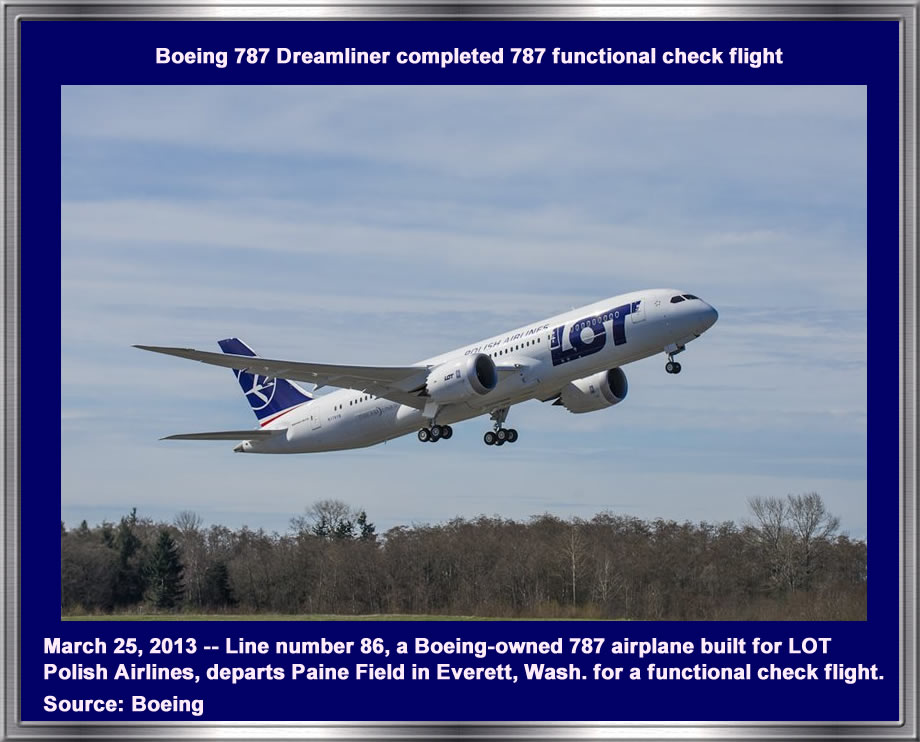

| "Boeing statement on completed 787 functional check flight"

March 25, 2013

|

"Working Together to Strengthen Our Safety Culture" Last Friday on March 22nd, 2013, FAA Administrator, Michael Huerta, presented a speech in Ritz Carlton, Crystal City which included that FAA will making action of doing the comprehensive review of the Boeing 787 Dreamliner’s critical systems including the design manufacture and assembly: FAA Administrator Michael Huerta said that "Working Together to Strengthen Our Safety Culture" The FAA is taking

very seriously its responsibility to establish aircraft safety standards and

certify new products and technologies which the Boeing 787 Dreamliner Battery

issue has been taking seriously and will analyze it until it’s satisfied for

them and for the public safety cause as number one priority to keep safe for

the people who fly day and night. The emphasis of the speech included: The FAA’s number

one priority is safety. It’s our mission, and we focus on it 24 hours a day. We have had a lot

of focus on the Boeing 787. We are continuing the review of the critical

systems of the aircraft, including the design, manufacture and assembly of the

Dreamliner. Our certification

team has worked more than 3,600 hours to support the safe return of this

aircraft to service. As part of this review, last week we approved Boeing’s

certification plan for a redesigned battery system. This is the first step in

the process to evaluate the 787’s return to flight. What the plan

includes is a redesign of the internal battery components to minimize a short

circuit within the battery and has insulated the battery cells to prevent

propagation from one cell to another. There are a total of eight cells in the

battery. They also have added a robust battery containment and venting system

to prevent a problem in the battery from spreading to the aircraft. The certification

plan includes a variety of ground tests and reviews that will enable Boeing to

demonstrate whether the proposed fix is going to work as designed, and whether

it complies with our regulations. We won’t allow the plane to return to service

unless we’re satisfied that the new design ensures the safety of the aircraft and

its passengers. Certification of

the 787, as with certification of any new aircraft, will continue to be a

collaborative effort between the FAA and manufacturers. Aviation, from its very beginning, has stretched technological boundaries. For more than five decades, the FAA has compiled a proven track record of safely introducing new technology and new aircraft, and that is really a credit to the aviation industry. FAA’s professional work and their dedication of aviation industry support for the public safety is all appreciated by the communities and aerospace industries including the Boeing Company.. "Our customers and their passengers have been incredibly patient as we have worked through this process and we thank them very sincerely for their continued support and confidence in the 787." said Boeing Commercial President and CEO, Ray Conner. FAA Administrator Michael P. Huerta stated that FAA is confident the plan that they approved on March 12, 2013 includes all the right elements to conduct a comprehensive evaluation of the battery system redesign that starts a testing process. Many are looking forward to see, resuming, and safely fly for the Boeing 787 Dreamliner flights as soon as possible including the communities and customers and even the Boeing Companies after new design is fully properly installed and approved by FAA.

|

||||||||||||

|

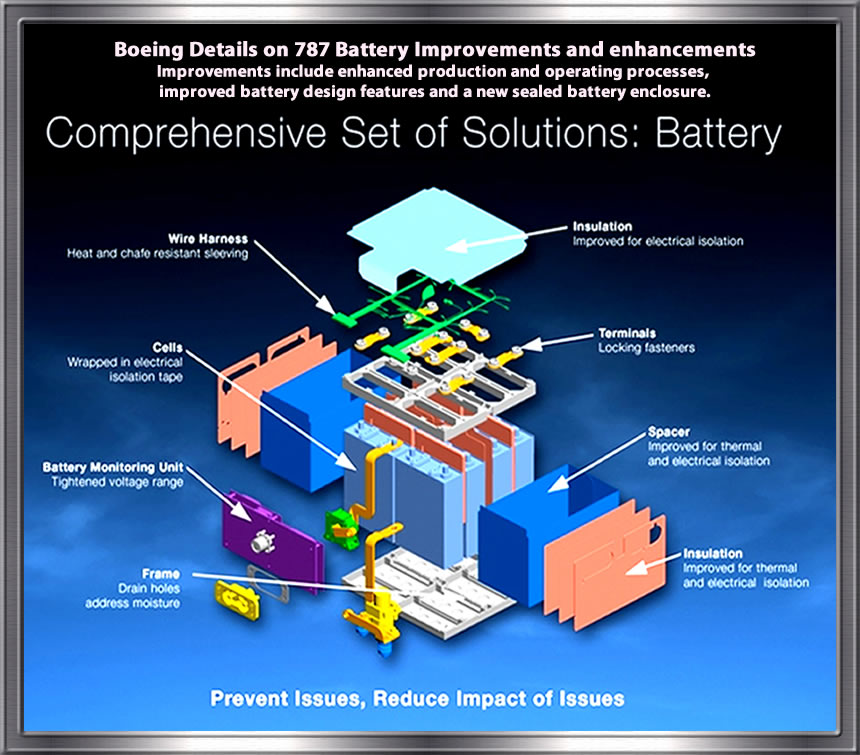

Boeing Provides Details on 787 Battery Improvements

|

||||||||||||||

|

|

||||||||||||||

|

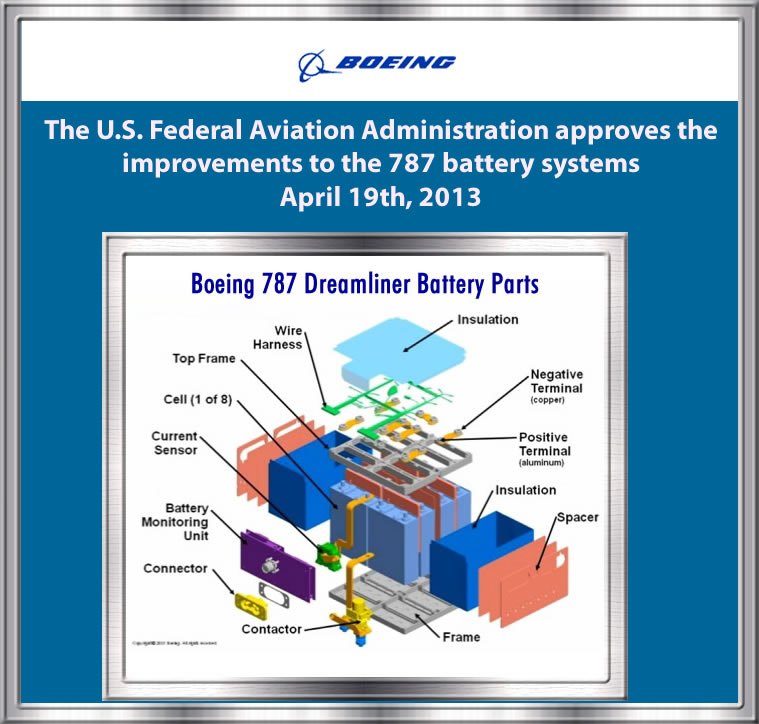

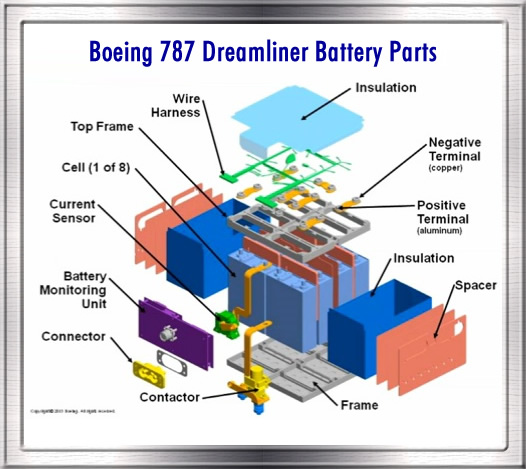

Boeing 787 Dreamliner Updates on Battery Issue FAA approves the certification for a battery solution EVERETT, Wash., March 12, 2013 /PRNewswire/ -- Boeing (NYSE: BA) has received approval from the U.S. Federal Aviation Administration (FAA) of the company's plan to test and certify improvements to the 787's battery system. Successful completion of each step within the plan will result in the FAA's approval to resume commercial 787 flights. "Our top priority is the integrity of our products and the safety of the passengers and crews who fly on them," said Boeing Chairman, President and CEO Jim McNerney. "Our team has been working around the clock to understand the issues and develop a solution based on extensive analysis and testing following the events that occurred in January. Today's approval from the FAA is a critical and welcome milestone toward getting the fleet flying again and continuing to deliver on the promise of the 787," he said. Ray Conner, president and chief executive officer of Boeing Commercial Airplanes, said that the company's focus has been on developing a permanent resolution. "Working with internal and external experts in battery technology, we have proposed a comprehensive set of solutions designed to significantly minimize the potential for battery failure while ensuring that no battery event affects the continued safe operation of the airplane," said Conner. "Our proposal includes three layers of improvements. First, we've improved design features of the battery to prevent faults from occurring and to isolate any that do. Second, we've enhanced production, operating and testing processes to ensure the highest levels of quality and performance of the battery and its components. Third, in the unlikely event of a battery failure, we've introduced a new enclosure system that will keep any level of battery overheating from affecting the airplane or being noticed by passengers," Conner said. Design feature improvements for the battery include the addition of new thermal and electrical insulation materials and other changes. The enhanced production and testing processes include more stringent screening of battery cells prior to battery assembly. Operational improvements focus on tightening of the system's voltage range. A key feature of the new enclosure is that it ensures that no fire can develop in the enclosure or in the battery. Additional details of the new design will be provided by Boeing in the days ahead. Boeing made its certification plan proposal to the FAA in late February. Today the agency agreed that the proposed changes and the detailed test plans address the conditions that resulted in the suspension of 787 operations. The FAA also granted Boeing permission to begin flight test activities on two airplanes: line number 86, which will conduct tests to demonstrate that the comprehensive set of solutions work as intended in flight and on the ground; and ZA005, which is scheduled to conduct engine improvement tests unrelated to the battery issue. Additional testing may be scheduled as needed. The certification plan calls for a series of tests that show how the improved battery system will perform in normal and abnormal conditions. The test plans were written based on the FAA's standards as well as applicable guidelines published by the Radio Technical Commission on Aeronautics (RTCA), an advisory committee that provides recommendations on ways to meet regulatory requirements. The RTCA guidelines were not available when the original 787 battery certification plan was developed. "We have a great deal of confidence in our solution set and the process for certifying it," said Conner. "Before 787s return to commercial service, our customers and their passengers want assurance that the improvements being introduced will make this great airplane even better. That's what this test program will do." Source: Boeing

|

||||||||||||||

|

Press Release – FAA Approves Boeing 787 Certification For Immediate Release March 12, 2013 WASHINGTON, D.C. – The Federal Aviation Administration (FAA) today approved the Boeing Commercial Airplane Company's certification plan for the redesigned 787 battery system, after thoroughly reviewing Boeing’s proposed modifications and the company’s plan to demonstrate that the system will meet FAA requirements. The certification plan is the first step in the process to evaluate the 787’s return to flight and requires Boeing to conduct extensive testing and analysis to demonstrate compliance with the applicable safety regulations and special conditions. “This comprehensive series of tests will show us whether the proposed battery improvements will work as designed,” said Transportation Secretary Ray LaHood. “We won’t allow the plane to return to service unless we’re satisfied that the new design ensures the safety of the aircraft and its passengers.” The battery system improvements include a redesign of the internal battery components to minimize initiation of a short circuit within the battery, better insulation of the cells and the addition of a new containment and venting system. “We are confident the plan we approved today includes all the right elements to conduct a comprehensive evaluation of the battery system redesign,” said FAA Administrator Michael P. Huerta. “Today’s announcement starts a testing process which will demonstrate whether the proposed fix will work as designed.” The certification plan requires a series of tests which must be passed before the 787 could return to service. The plan establishes specific pass/fail criteria, defines the parameters that should be measured, prescribes the test methodology and specifies the test setup and design. FAA engineers will be present for the testing and will be closely involved in all aspects of the process. The FAA also has approved limited test flights for two aircraft. These aircraft will have the prototype versions of the new containment system installed. The purpose of the flight tests will be to validate the aircraft instrumentation for the battery and battery enclosure testing in addition to product improvements for other systems. The FAA will approve the redesign only if the company successfully completes all required tests and analysis to demonstrate the new design complies with FAA requirements. The FAA’s January 16, 2013 airworthiness directive, which required operators to temporarily cease 787 operations, is still in effect, and the FAA is continuing its comprehensive review of the 787 design, production and manufacturing process. ----------------------------------------------------------------------------------- |

||||||||||||||

|

According to Boeing Randy's journal, Dated March 12, 2013, Randy said that "Today, we got good news from the FAA that they’ve given us the go ahead to start testing and certifying our solution to the 787 battery issue. By successfully completing each step in that plan, the FAA will allow the fleet to return to service..." Flight test activities will begin on two airplanes. Line Number 86 will conduct tests to demonstrate what Boeing company's solution works as intended in flight and on the ground. Meanwhile, ZA005 will conduct engine improvement tests unrelated to the battery issue. Boeing may do additional testing if needed. The 787 Dreamliner applies breakthrough technologies to an all-new airplane design. The advanced features of the 787 increase efficiency, simplify airplane ownership and operation, and significantly improve the air travel experience. Boeing 787 Dreamliner ordered by the great company like this link shows. Boeing Commercial President, CEO Ray Conner stated that Boeing's proposal includes three layers of improvements with the following:

According to FAA Administrator Michael P. Huerta, FAA is confident the plan that thay aproved which includes all the right elements to conduct a comprehensive evaluation of the battery system redesign. This announcement starts a testing process which will demonstrate whether the proposed fix will work as designed which FAA has approved limited test flights for two aircraft. These aircraft will have the prototype versions of the new containment system installed. The purpose of the flight tests will be to validate the aircraft instrumentation for the battery and battery enclosure testing in addition to product improvements for other systems that carrys the safety of the passengers and crews who fly on them is the top priority which was emphasized by Boeing Chairman, President and CEO Jim McNerney.

|

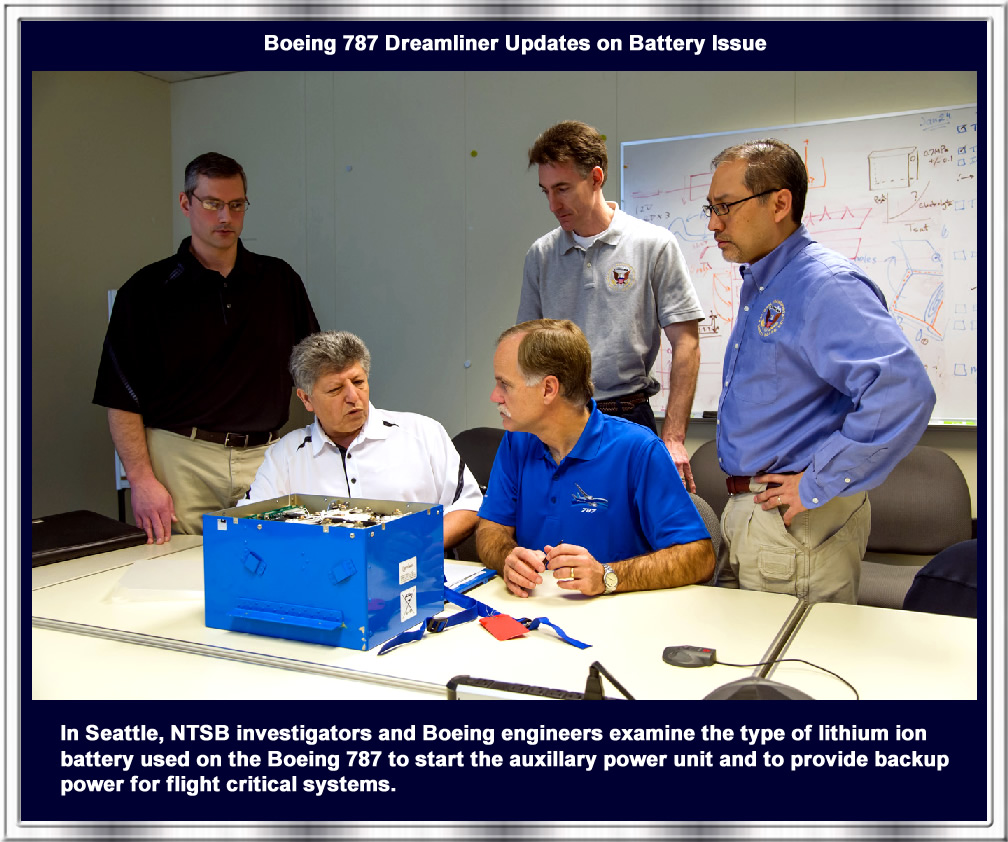

Boeing 787 Dreamliner Updates on Battery Issue

Boeing: Battery Crisis Investigation continues

by NTSB and Boeing

|

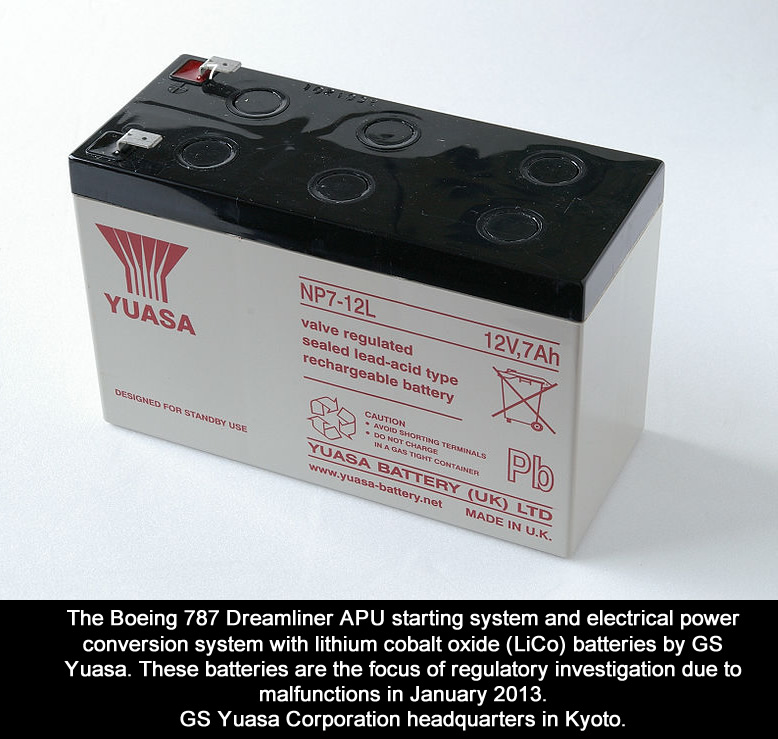

The NTSB’s investigation of the JAL 787 battery fire is continuing along with Boeing’s continuing support and working together. Below are activities that are either currently underway or planned by each of the investigative groups. The scope of the testing and examinations may change as investigative data are collected: System Safety and Certification Group are working deligently accordingly with the following: Examine the safety assessment process used

to evaluate the lithium-ion battery design, including the underlying

assumptions, tests, and data that support conclusions used in the analysis. Review the testing and analysis done by

Boeing, Thales, and GS Yuasa to characterize the cell and battery failure

conditions. Document and examine the flow-down of design and manufacturing requirements that have an impact on the failure modes of interest within the battery and cells. Research and document the evolution of

safety analysis standards as they relate to evaluating and mitigating safety

risks for lithium-ion battery cells and battery packs. Review and document the certification

process steps taken to evaluate the battery design against the FAA’s special

conditions and examine the roles and responsibilities of the FAA, Boeing,

Thales, and GS Yuasa in that process. Environmental Issue Area Document and evaluate the toxicity of

combustion byproducts that accompany lithium-ion battery fires. Document 787 lower lobe ventilation system

strategies for clearing combustion byproducts resulting from lithium-ion

battery fires to evaluate the effectiveness of mitigation strategies used to

address occupant protection certification requirements. The NTSB’s investigation into the probable cause of the 787 battery fire at BOS is continuing. The NTSB is also continuing to review the design, certification, and manufacturing processes for the 787 lithium-ion battery system while the Boeing Company is continue to support and working together. Further detail information is available via NTSB Meanwhile, Boeing continue to monitoring the 787 which The Boeing average number of flights AHM monitors on a typical day 787s send an aerage of 787verage of 136 reports per day. Which AHM works for Data from onboard systems and engines is routinely captured in flight and transmitted in real time to the airline’s ground operations. When any issue surfaces, major or minor, airline personnel receive alerts delivered through the Internet, e-mail, fax or pager services.

|

|

Boeing's high tech customer service is continue which the AHM has been on board the 787 Dreamliner since the beginning. So far, AHM has monitored 50,000 787 flight-hours which was enabled Boeing to support customers in near real time, increasing 787 schedule reliability. For example, when AHM discovered a software issue with flight controls that began to cause delays in the fleet, it became clear that the airline could not wait for the next regularly scheduled software update to address the problem. Boeing fixed it immediately. Detail information available via Boeing site: |

|

|

Sources:Boeing, FAA, Bloomberg, |

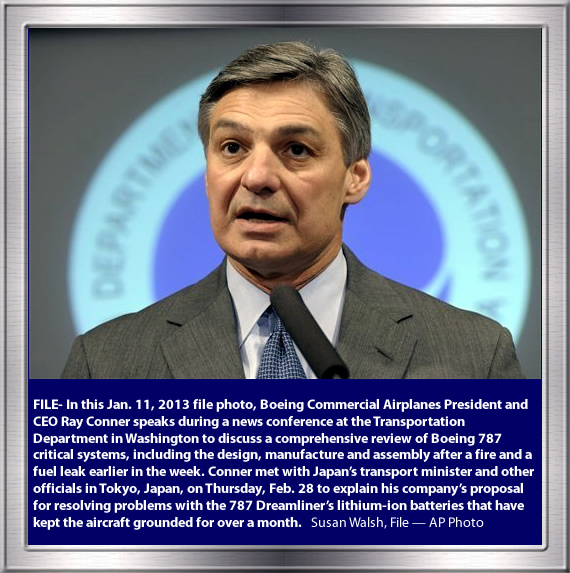

Boeing: Battery Resolution FoundF

Boeing Commercial Co. President and CEO, Ray Conner

with Japanese officials in Tokyo

February 28th, 2013

|

|

|

|

According to Reuters, Dated, February 28th, 2013, The Boeing has the PERMANENT SOLUTION for the Battery solution. Following talks with Japan's transport minister Akihiro Ota on Thursday, Boeing's Conner said the company's proposal to the FAA was a permanent solution, not an interim fix. "We see nothing in the technology that tells us that it is not the appropriate thing to do. The solution set we put in place provides three layers of protection," he said in response to a reporter's question on whether Boeing would consider dropping the lithium-ion battery from the lightweight, fuel-efficient Dreamliner. "We feel this solution takes into account any possible incident that may occur, any casual factor that could cause an event, and we are very confident we have a fix that will be permanent and allow us to continue with the technology." Earlier, Boeing spokesman Marc Birtel said investigations had not shown that overcharging was a factor, and he noted the 787 had quadruple-redundant protection against overcharging. He did not respond directly to comments about GS Yuasa, but said Boeing was coordinating with key suppliers. No comment was immediately available from Securaplane Technologies Inc, a U.S. unit of Britain's Meggitt Plc, which makes the charger for the 787 batteries. All Nippon Airways and Japan Airlines operate nearly half of the Dreamliners that Boeing has delivered to date. ----------------------------------- The Boeing Exteded Global Supply Chain: 783 million parts are procured in one year: 737 (400) 767 (3.1 million parts) 787 (2.3 million parts) 777 (3 million parts) 747-8 (6 million parts) $28 Billion psend 5,400 factories 500,000 people around the world. All of these global Boeing suppliers also applyting the highest technologies up to date. The world cannot afford not to be making 1000 percent for sure to be safe as maximum as possible like all human and all possilbe living while we are making the fastest global communication and global transportation around the world. If we not carefully using the product, it could be loosing human lifes in a second which is the top priority for the safety issues for any compannies, there is no differences for Boeing suppliers and partners. Deputy Transportation Secretary John Porcari, FAA Administrator Michael P. Huerta and other FAA officials have met with senior executives from The Boeing Company and discussed on February 22nd, 2013 which the status of ongoing work to address 787 battery issues. The FAA is reviewing a Boeing proposal and will analyze it closely. The safety of the flying public is our top priority and FAA won't allow the 787 to return to commercial service until we're confident that any proposed solution has addressed the battery failure risks. Meanwhile, Boeing Commercial President, CEO Ray Conner have met with Japan's transport minister Akihiro Ota San on February 28th, 2013. The report shows that the Boeing's President, CEO, Ray Conner said the company's proposal to the FAA was a permanent solution, not an interim fix. The U.S. Federal Aviation Administration is considering the plan. All 50 of the technologically-advanced Dreamliners in service have been grounded since mid-January after a battery fire on a Japan Airlines Co Ltd 787 at Boston airport and a second battery incident on an All Nippon Airways Co Ltd flight in Japan. According to AP, The president of All Nippon Airways, Boeing's biggest single customer said on Friday that he believes the U.S. manufacturer has made progress in resolving problems with the aircraft's lithium-ion batteries. said Friday that he believes the U.S. manufacturer has made progress in resolving problems with the aircraft's lithium-ion batteries. Although, the 787s being grounded worldwide for over a month, depends partly on the approval process by the U.S. Federal Aviation Administration, said Shinichiro Ito san, who took up the positions of president of ANA Holdings Inc. and chairman of All Nippon Airways on Thursday.

"It isn't up to me to say how far they've gotten in resolving this," Ito said, after ANA management met earlier this week with Boeing Comercial President and CEO Ray Conner. While Boeing Commercial President and CEO Ray Conner visiting Tokyo, his was discussing to Japanese transport regulators and airlines his company's proposal for fixing the problems with overheating of the 787's lithium-ion batteries. "If the battery problem is resolved, I am confident the aircraft will be fine," Ito san said. "Once the (Boeing proposal) is approved, we will discuss when to resume operations." and report shows that ANA is expecting to be released and capable to fly before June with according to the tight schedule to be fit which ANA has extended the cancellations of its 787 flights to May 31, with the total number of flights affected at nearly 3,600, involving some 167,820 passengers. JAL has cancelled its 787 flights through Mar. 30. Boeing's plan, presented to U.S. regulators last week, calls for revamping the batteries to prevent potential short-circuiting from spreading from any one battery cell to others. Officials in the U.S. said Boeing would fix the problem with the batteries overheating by having more robust ceramic insulation around each of the battery's eight cells so as to prevent any thermal runaway, a chemical reaction that leads to progressively hotter temperatures that was found in damaged batteries in JAL and ANA incidents. "This solution takes into account any possible event that might occur," Conner said. "We see nothing in the technology that would tell us it's not the appropriate thing to do," he said. The aircraft has suffered from early in-service problems, notably fires on board related with its lithium-ion batteries. These systems are being reviewed by both the FAA and the Japanese aviation agency. On January 16, 2013, the FAA issued an emergency airworthiness directive that grounds all 787s in the U.S. The EASA, Japanese Transport Ministry, India's Directorate General of Civil Aviation (DGCA), and Chile's Dirección General de Aeronautica Civil (DGAC) followed suit and grounded the Dreamliners in their respective jurisdictions. The Boeing 787 Dreamliner soon to be overcome like all of us and many are having expectation, in time service of FAA with an economical and quality - reliable service which they have been in many ways.

|

||

|

FAA Press ReleaseF The safety of the flying public is FAA's top priority February 22nd, 2013 |

||

|

According to FAA, Press release immediate release dated February 22nd, 2013, ---------------------------- |

Boeing 787 Dreamliner Updates on Battery Issue

February 12th, 2013

Boeing Continues to progress on Battery Issue

Boeing says

"Lithium Battery Is The Right Technology"

|

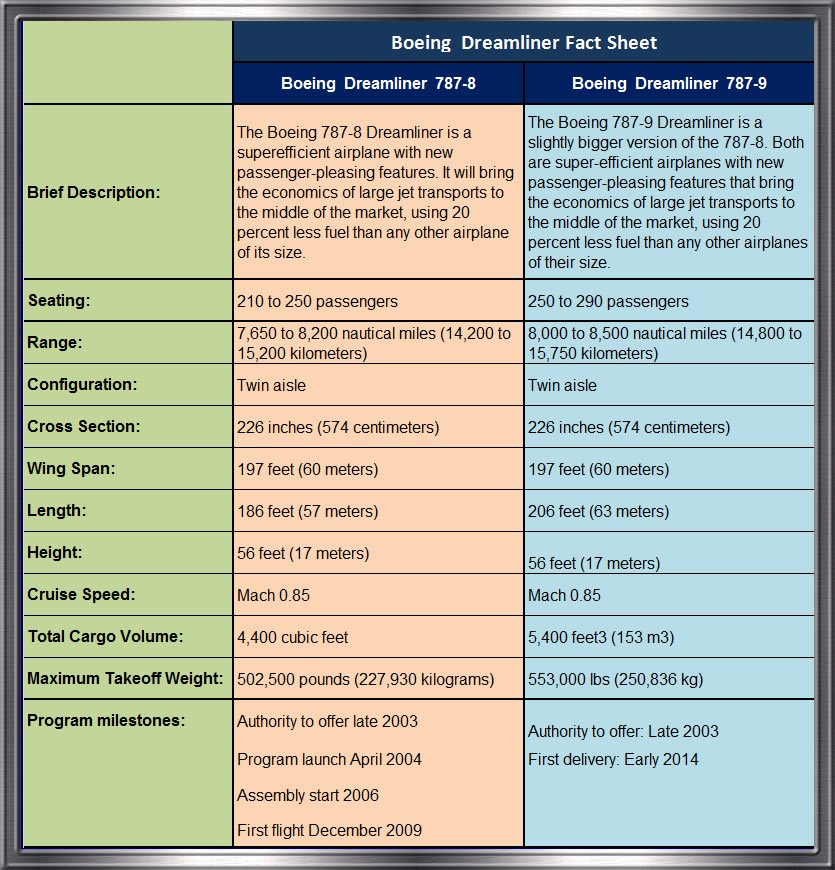

Mike Sinnett, 787 VP and Chief Project Engineer, provided a brief overview of the Electrical and battery systems for Boeing 787 Dreamliner on February 12, 2013. Boeing described all about the Lithium Ion Batteries that how the efficient energy creation, distribution for use of better power control, and how the battery makes the advantages. Meanwhile Boeing stressed "Lithium Battery Is The Right Technology". Mike Sinnett, 787 VP and Chief Project Engineer describes More efficient energy creation, distribution for use of Better power control which describes automatic monitoring for better airplane availability Airplane Health Management, More fuel efficient, Fewer maintenance tasks, Lower maintenance costs, Better reliability, Less drag and reduces noise. Boeing also described detail of Parts of the 787 battery via presentation.

Boeing also emphasized that how the battery will take the advantages which will give more energy, more quickly, re-charges faster, lighter which reduces the weigh 30 percent less and it is effectively more compact. Boeing also described the system that makes controls and distributes power to run airplane systems to Flight deck displays, Hydraulic system, lighting, in-flight entertainment and for many others. Even so, redundant systems and backups provide layer of safety which it can run on electricity from ground carts on the ground for airplane. |

||||||||

|

||||||||

|

NTSB is under investigating APU battery fault for Boeing 787 Dreamliner since January 2013 after the battery incident was happened in January, 2013. And Main battery fault is under investigation by the JTS. Boeing has history 2.2 milion cell-hours in operations (includes Boeing and airline ground and flight hours, eight cells per battery) for Prior to January 2013. Boeing also 50,000 hours flying and there was No battery incident events on an airplane and Standard battery issues, comparable with other airplanes. Boeing Described all about the Boeing 787 Dreamliner Battery proceeding in Boeing. According to the Bloomberg news dated Feb 21st, 2013, Boeing will present a battery redesign for the 787 Dreamliner tomorrow in a bid to satisfy regulators’ safety concerns and get the jet back into the air within weeks, people with knowledge of the proposal said. Bloomberg also reported that A team led by Boeing Commercial Airplanes President Ray Conner is scheduled to meet in Washington with the U.S. Federal Aviation Administration, including Administrator Michael Huerta, the people said. Any repairs would be subject to FAA approval, and the agency isn’t expected to act immediately unless tests show the fixes can ensure safety, the people said. New York Times dated Feb. 20th, 2013, Boeing has developed possible fixes for the battery problems in its grounded 787 jets and could have them back in the air within two months, industry and federal officials said Wednesday. The officials said Boeing has narrowed down the ways the lithium-ion batteries on the jetliners could fail, and believes that adding insulation between the cells of the batteries and making other changes would provide enough assurance that they would be safe to use. Raymond L. Conner, the president of Boeing’s commercial airplane division, plans to propose the fixes in a Friday meeting with Michael P. Huerta, the head of the Federal Aviation Administration. Mr. Huerta is not expected to approve the changes immediately, but the meeting is likely to start a high-level discussion on the standards Boeing needs to meet as it tests the fixes and seeks to get the planes flying again. Boeing’s plan could be a pivotal moment in the history of the innovative fuel-efficient planes. Mr. Huerta and regulators around the world grounded the planes in mid-January after a battery caught fire on one jet parked at the Boston airport and smoke forced another 787 to make an emergency landing in Japan. Investigators have not determined what caused those problems. But Boeing’s engineers have worked closely with the F.A.A. and outside experts to identify ways in which the batteries could have failed, and Boeing is now asking the government to sign off on a calculation that they have now come up with a safer design. Given the risks in moving ahead, federal officials said, the F.A.A. has insisted behind the scenes that Boeing needed to come up with changes to prevent failures at the same time as it proposed further steps to wall off problems with the batteries and vent any smoke or fire outside the planes. ¶ Boeing officials said they had also hoped to make all the fixes at once rather than dividing them into temporary and longer-term changes. By delaying some changes, Boeing could have been exposed to more problems. As a result, one big change under Boeing’s plan would be to redesign the batteries to place insulation inside and around each of the eight cells to minimize the risk that a short circuit or fire in one of the cells could spread to the others, as investigators have said occurred on the battery that caught fire in Boston on Jan. 7. Boeing might also adjust how tightly the batteries are packed. Boeing would make other changes within the batteries to reduce the chance that vibrations, swelling or moisture could cause problems, industry officials said. Boeing has already been testing some of the changes. The plane maker believes it could rebuild the batteries by next month on the 50 jets that have been delivered to airlines. But federal officials are likely to move more slowly and demand more tests and assurances, and the final decision could rest with Mr. Huerta’s supervisors at the Transportation Department. Federal officials said that if the fixes check out, the jets could start flying again by April. Boeing will also have to win back the confidence of the flying public. The company has orders for 800 additional planes. The jets rely as well on lightweight carbon composites and more efficient engines. The lithium-ion batteries weigh less but provide more energy than conventional batteries, and the 787s make greater use of them than other planes. The stakes are substantial for Boeing, which will have to pay penalties to some of the airlines that have been unable to use them. Boeing also cannot deliver more of the planes while they are grounded. Boeing awarded the contract for the batteries to GS Yuasa, a Japanese firm, in 2005, and it won approval from the F.A.A. to use the batteries in 2007. Concerned about fires with smaller lithium-ion batteries in cellphones and laptops, the agency placed special conditions on Boeing’s use of the batteries that required containment and venting measures that have proved inadequate. The U.S. National Transportation Safety Board has concluded a short-circuit in a battery cell led to the Jan. 7 fire in Boston, which spread to other cells. The reason for the short hasn’t been identified, NTSB Chairman Debbie Hersman said on Jan. 24. All eight of the battery cells on the ANA Dreamliner sustained thermal damage, Japan Transport Safety Board chief Norihiro Goto said yesterday. Damage to the electrodes may have been caused by overheating from thermal runaway within the cell. He said further investigation is needed. Fox news reported on February 20th, 2013, Boeing (BA) says progress is being made to fix its battery problems and return the grounded fleet of 787 Dreamliner jets back to service. Hundreds of engineering and technical experts are working around the clock 24/7. The FAA approved Boeing’s battery in 2007 under “special conditions” prohibiting hazardous gas from accumulating in the plane if a battery overheated or caught fire. It also said a fire couldn’t be allowed to damage critical equipment or the aircraft’s structure. With the words of stress, 100 minus 3 years of Boeing history (founded by William Boeing) which Boeing has history of 2.2 milion cell-hours in operations (includes Boeing and airline ground and flight hours, eight cells per battery) for Prior to January 2013. Boeing also 50,000 hours flying and there was No battery incident events on an airplane and Standard battery issues, comparable with other airplanes. Boeing 787 manufacturing and supply teams spent years applying a rigorous and disciplined approach to ensure the Dreamliner set new standards in performance, efficiency and safety. The Boeing team conducted the most comprehensive testing and certification efforts in history on this program around the clock 24/7 and the Boeing says, safety is the first priority for the customers to fly.

|

||||||||

|

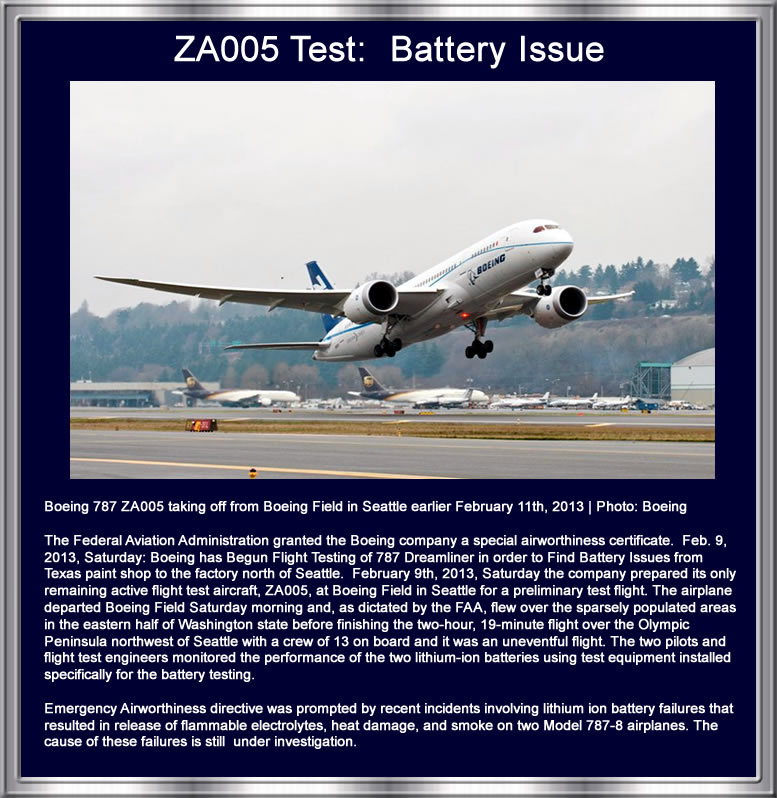

February 9th, 2013 ZA005, Boeing's fifth 787 airplane, conducts flight testing ZA005, Boeing's fifth 787 flight test airplane, departed from Boeing Field at 12:32 p.m. Pacific time on Saturday, Jan. 9, with a crew of 13 onboard (Boeing pilots and flight test personnel). The flight lasted 2 hours and 19 minutes, landing back at Boeing Field at 2:51 p.m. Pacific time. The crew reports that the flight was uneventful. During the flight, the crew monitored the performance of the main and APU batteries. Special equipment onboard ZA005, which is currently the only member of the Boeing 787 flight test fleet in service, allowed the crew to observe and record detailed battery performance in normal flight conditions. Data gathered during the flight is considered part of the investigations into the 787 battery events that occurred in January. For that reason, we cannot share any additional details. We have no flights planned for ZA005 Sunday, but plan to resume flights early this coming week. As a matter of long-standing practice, we do not provide flight schedules in advance of flight plans being filed. Takeoff photos from today's flight have been posted here: http://www.flickr.com/photos/theboeingcompany/sets/72157632730482850/. |

|

----------------------------------------------------------------

Jan 16th, 2013: Emergency Airworthiness directive was prompted by recent incidents involving lithium ion battery failures that resulted in release of flammable electrolytes, heat damage, and smoke on two Model 787-8 airplanes. The cause of these failures is currently under investigation. These conditions, if not corrected, could result in damage to critical systems and structures, and the potential for fire in the electrical compartment in order to preventing all the relevant information and determined the unsafe condition described previously is likely to exist or develop in other products of the same type design. Therefore, AD required modification of the battery system, or other actions, in accordance with a method approved by the Manager, Seattle Aircraft Certification Office (ACO), FAA. Feb. 7, 2013,Thursday: The Federal Aviation Administration granted the Boeing company a special airworthiness certificate. Feb. 9, 2013, Saturday: Boeing Begins Flight Testing of 787 Dreamliner in order to Find Battery Issues from Texas paint shop to the factory north of Seattle. Same day, Saturday the company prepared its only remaining active flight test aircraft, ZA005, at Boeing Field in Seattle for a preliminary test flight. The airplane departed Boeing Field Saturday morning and, as dictated by the FAA, flew over the sparsely populated areas in the eastern half of Washington state before finishing the two-hour, 19-minute flight over the Olympic Peninsula northwest of Seattle with a crew of 13 on board and it was an uneventful flight. The two pilots and flight test engineers monitored the performance of the two lithium-ion batteries using test equipment installed specifically for the battery testing. Feb. 11, 2013, Monday: Feb 11, 2013, Monday : ZA005 was again back in the skies above eastern Washington on the second flight test. The test pilots flight: Randy Neville and Mike Bryan, the same pilots flew as last year during the 787 flight. The airplane was the first to fly with the General Electric engines (Rolls Royce engines power the other 787s), and was being used for flight test work related to the next Dreamliner model, the slightly longer 787-9. Boeing continues to analyze and investigating the battery issues that occured on January 16th, 2013 until the complete resultuion is resolved which the Boeing Engineers are constantly testing the flight proceeding accordingly all time. |

|

|

Sources:Boeing, WIRDED and FAA youtube, wikipedia and Airworthiness Directive catch4all.com, Sandra Englund February 14th, 2013. |

|

According to Boeing Dated, February 7th, 2013, Boeing will soon resume limited 787 flight test activities with a flight of ZA005, the fifth flight test airplane. This activity has been approved by the U.S. Federal Aviation Administration. This flight test activity will allow Boeing to conduct testing of the in-flight performance of the airplane's batteries, which will provide data to support the continuing investigations into the cause of the recent 787 battery incidents. Flight test activities are different from commercial flight operations and, because of the test environment, special considerations are always in place when the FAA permits such operations. With that said, while our work to determine the cause of the recent battery incidents continues in coordination with appropriate regulatory authorities and investigation agencies, we are confident that the 787 is safe to operate for this flight test activity. To provide additional precautions, we have implemented additional operating practices for test flights, including a one-time pre-flight inspection of the batteries, monitoring of specific battery-related status messages, and a recurring battery inspection. The company has an extensive team of hundreds of experts working around the clock, focused on resolving the 787 battery issue and returning the 787 fleet to full flight status. We are working this issue tirelessly in cooperation with our customers and the appropriate regulatory and investigative authorities. At the same time, a dedicated team of professionals is continuing to produce 787s and prepare them for delivery. As we have said before, the entire Boeing team deeply regrets the impact that recent events have had on our customers and their passengers. We are doing all we can to reach a resolution and begin again to meet their expectations.g Source: Boeing |

February 7th, 2013

According to FAA Press Release – Statement from Secretary LaHood and FAA

For Immediate Release

February 7, 2013

As part of our ongoing efforts to determine the root cause of recent Boeing 787 lithium-ion battery incidents, the FAA will permit Boeing to conduct test flights of 787 aircraft to gather additional data. The traveling public’s safety is our highest priority. These test flights will be an important part of our efforts to ensure the safety of passengers and return these aircraft to service.

Test flights are commonly used as part of research and development. In this case, the primary purpose of the test flights will be to collect data about the battery and electrical system performance while the aircraft is airborne.

As with all test flights, these will be subject to a number of restrictions, including extensive pre-flight testing and inspections and in-flight monitoring in order to ensure the highest levels of safety. The flights will be conducted in defined airspace over unpopulated areas.

The test flights will be conducted through a Special Airworthiness Certificate (for the purpose of Research and Development) under the following requirements:

- Before flight, the crew must perform a number of inspections to verify that the batteries and cables show no signs of damage.

- Pre-flight checklist will include a mandatory check for specific status messages that could indicate possible battery problems.

- While airborne, the crew must continuously monitor the flight computer for battery related status messages, and land immediately if one occurs.

- Before the initial test flight, the crew must inspect the airplane’s smoke barriers and insulation to verify that they meet the approved design.

- Experimental research and development flights are flown with Boeing aircrews that include only personnel essential to the flight.

In addition to the FAA’s root cause analysis, the FAA is conducting a comprehensive review of the 787’s critical systems, including the aircraft’s design, manufacture and assembly.

February 7th, 2013

According to NTSB press release dated February 7th, 2013: NTSB identifies origin of JAL Boeing 787 battery fire; design, certification and manufacturing processes come under scrutiny.

WASHINGTON - At a news conference today, NTSB Chairman Deborah A.P. Hersman identified the origin of the Jan. 7 battery fire that occurred on a Japan Airlines 787 parked at Boston Logan Airport, and said that a focus of the investigation will be on the design and certification requirements of the battery system.

"U.S. airlines carry about two million people through the skies safely every day, which has been achieved in large part through design redundancy and layers of defense," said Hersman. "Our task now is to see if enough - and appropriate - layers of defense and adequate checks were built into the design, certification and manufacturing of this battery."

After an exhaustive examination of the JAL lithium-ion battery, which was comprised of eight individual cells, investigators determined that the majority of evidence from the flight data recorder and both thermal and mechanical damage pointed to an initiating event in a single cell. That cell showed multiple signs of short circuiting, leading to a thermal runaway condition, which then cascaded to other cells. Charred battery components indicated that the temperature inside the battery case exceeded 500 degrees Fahrenheit.

As investigators work to find the cause of the initiating short circuit, they ruled out both mechanical impact damage to the battery and external short circuiting. It was determined that signs of deformation and electrical arcing on the battery case occurred as a result of the battery malfunction and were not related to its cause.

Chairman Hersman said that potential causes of the initiating short circuit currently being evaluated include battery charging, the design and construction of the battery, and the possibility of defects introduced during the manufacturing process.

During the 787 certification process, Boeing studied possible failures that could occur within the battery. Those assessments included the likelihood of particular types of failures occurring, as well as the effects they could have on the battery. In tests to validate these assessments, Boeing found no evidence of cell-to-cell propagation or fire, both of which occurred in the JAL event.

The NTSB learned that as part of the risk assessment Boeing conducted during the certification process, it determined that the likelihood of a smoke emission event from a 787 battery would occur less than once in every 10 million flight hours. Noting that there have been two critical battery events on the 787 fleet with fewer than 100,000 flight hours, Hersman said that "the failure rate was higher than predicted as part of the certification process and the possibility that a short circuit in a single cell could propagate to adjacent cells and result in smoke and fire must be reconsidered."

As the investigation continues, which will include testing on some of the batteries that had been replaced after being in service in the 787 fleet, the NTSB will continue to share its findings in real time with the FAA, Boeing, the Japan Transport Safety Board, and the French investigative agency, the Bureau d'Enquêtes et d'Analyses.

"The decision to return the fleet to flight will be made by the FAA, which underscores the importance of cooperation and coordination between our agencies," Hersman said.

She also announced that the NTSB would release an interim report of factual findings within 30 days.

Additional information, including a video of the today's media briefing, the PowerPoint presentation, the FAA's Special Conditions for the B-787 battery system, and related documents, can be accessed at http://go.usa.gov/4K4J.

The NTSB will provide additional factual updates as developments warrant. To be alerted to any updates or developments, follow the NTSB on Twitter at www.twitter.com/ntsb.

NTSB Media Contact:

Office of Public Affairs

490 L'Enfant Plaza,

SW

Washington, DC 20594

(202) 314-6100

Kelly Nantel

kelly.nantel@ntsb.gov

or Peter

Knudson

peter.knudson@ntsb.gov

FAA is confident about the safety of this 787 Dreamliner aircraft. However FAA is concerned about these incidents and FAA will conduct this review until they are satisfied.

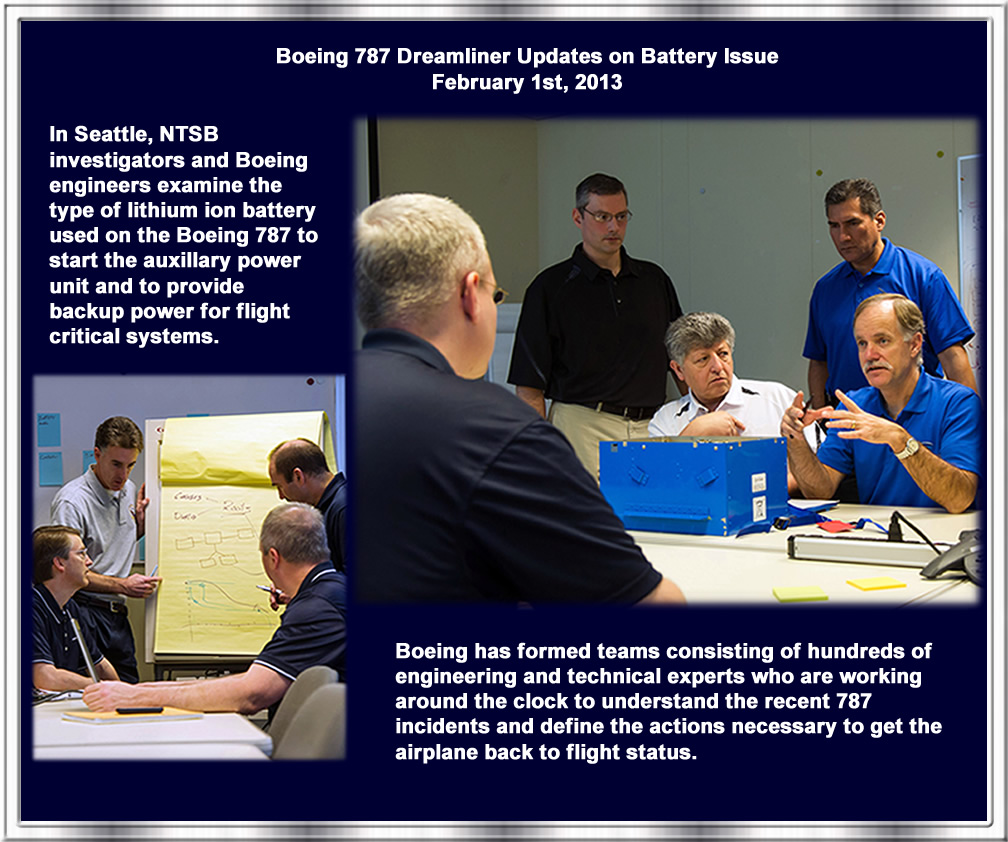

Boeing has formed teams consisting of hundreds of engineering and technical experts who are working around the clock to understand the recent 787 incidents and define the actions necessary to get the airplane back to flight status.

Boeing has asked the Federal Aviation Administration for permission to conduct test flights of the 787 Dreamliner to gather more information to help solve the aircraft’s battery problems, the company confirmed. The request for the test flights is “currently under evaluation by the FAA,” said Boeing spokesman Scott Lefeber, in an email. A source at the FAA also confirmed the Boeing request.

Boeing welcomes the progress reported by the U.S. National Transportation Safety Board (NTSB) in the 787 investigation, including that the NTSB has identified the origin of the event as having been within the battery. The findings discussed today demonstrated a narrowing of the focus of the investigation to short circuiting observed in the battery, while providing the public with a better understanding of the nature of the investigation.

The company remains committed to working with the NTSB, the U.S. Federal Aviation Administration (FAA) and our customers to maintain the high level of safety the traveling public expects and that the air transport system has delivered. We continue to provide support to the investigative groups as they work to further understand these events and as we work to prevent such incidents in the future. The safety of passengers and crew members who fly aboard Boeing airplanes is our highest priority.

The 787 was certified following a rigorous Boeing test program and an extensive certification program conducted by the FAA. Boeing provided testing and analysis in support of the requirements of the FAA special conditions associated with the use of lithium ion batteries. Boeing is in working collaboratively to address questions about their testing and compliance with certification standards, and Boeing is continue to make changes that lead to improved testing processes and products. Meanwhile, NTSB continues to corporate and working together with the Boeing, FAA, the Japan Transport Safety Board, and the French investigative agency for the battery issues may had links.

The Boeing 787 Dreamliner soon to be overcome like all of us and many are having expectation, in time service of FAA with an economical and quality - reliable service which they have been in many ways.

|

|

Sources:Boeing, Puget Sound Business Journal,\and FAA and NTSB catch4all.com, Sandra Englund February 7th, 2013. |

FAA is moving forward

Boeing 787 Dreamliner Battery Issue

According to FAA January, 23rd, 2013, FAA speech, FAA is moving forward with a review of the critical systems of the Boeing 787. FAA continues to support to meet the highest safety standards. FAA believes this is a safe aircraft. To validate the work conducted during the certification process, FAA is going to work with Boeing to conduct a review of all critical systems of the 787, including design and production in order to meet the FAA regulation which FAA wants to see the entire picture and do not want to just focus on individual events and determine the root causes of these recent events in order to prevent the same incident in Jan. 7th, 2013. FAA will put an emphasis on the electrical system in the airplane which includes components such as batteries and power distribution panels. In addition, FAA will look at how the electrical and mechanical systems of the airplane interact with one another which will determine the root causes of these recent events so they won’t happen again.

On January 11th press release shows that last month, FAA issued an airworthiness directive that required inspection of fuel line couplings in the engine pylons to verify that they were correctly assembled and installed which the work has been completed on all 787s operated by the U.S. carrier.

FAA emphasize that the 787 has numerous back-up systems and redundancies, and these are there for safety same with all aircrafts. The Boeing 787 is an innovative aircraft and the FAA logged 200,000 hours of technical work on the type certification. Our crews flew on numerous test flights.

On January 16th, FAA stated that the FAA will issue an emergency airworthiness directive (AD) to address a potential battery fire risk in the 787 and require operators to temporarily cease operations which was the Boston battery fire on January 7 and a separate battery failure that forced a second 787 to make an emergency landing in Japan a week later. FAA addressed that the Boeing 787 aircraft must demonstrate to the Federal Aviation Administration (FAA) that the batteries are safe before further flight, operators of U.S.-registered. The FAA will continue to work with the manufacturer and carriers to develop a corrective action plan to allow the U.S. 787 fleet to resume operations as quickly and safely as possible.

|

|

|

FAA is confident about the safety of this 787 Dreamliner aircraft. However FAA is concerned about these incidents and FAA will conduct this review until they are satisfied. Meanwhile, FAA introduced CEO of Boeing Commercial Airplanes Ray Conner during their special speech and press release on January 11th, 2013.

The FAA's roles include:

The Federal Aviation Administration (FAA) is the national aviation authority of the United States of America. An agency of the United States Department of Transportation, it has authority to regulate and oversee all aspects of civil aviation in the U.S.

Their mission is to improve the Nation's aviation safety record by conveying safety principles and practices through training, outreach, and education. At the same time, FAASTeam Managers and Program Managers will establish meaningful aviation industry alliances and encourage continual growth of a positive safety culture within the aviation community.

Meanwhile, Boeing has asked the Federal Aviation Administration for permission to conduct test flights of the 787 Dreamliner to gather more information to help solve the aircraft’s battery problems, the company confirmed. The request for the test flights is “currently under evaluation by the FAA,” said Boeing spokesman Scott Lefeber, in an email. A source at the FAA also confirmed the Boeing request. The Boeing 787 Dreamliner soon to be overcome like all of us and many are having expectation, in time service of FAA with an economical and quality - reliable service which they have been in many ways...... .

|

|

Sources:Boeing, yahoo, wikipedia , Puget Sound Business Journal,\and FAA catch4all.com, Sandra Englund February 6th, 2013. |

Boeing 787 Dreamliner Updates on Battery Issue

February 4th, 2013

According to the Reuters, dated February 4th 2013, reported by Andrea Shalal-Esa that The Boeing 787 investigation making progress which describes detailed with the following contents:

WASHINGTON (Reuters) - U.S. officials on Friday said they are making progress in their investigation of a battery fire on a Boeing Co 787 Dreamliner in Boston this month, as the grounding of Boeing's entire fleet of 787s stretched into a third week.

All 50 Boeing 787s remain grounded as authorities in the United States, Japan and France investigate the Boston battery fire on January 7 and a separate battery failure that forced a second 787 to make an emergency landing in Japan a week later.

The U.S. safety board said it continued to look at flight data recorded aboard the 787 aircraft involved in the January 7 event at Boston airport for any information about the performance of the lithium-ion battery that caught fire, and its charging system, which was built by Securaplane, a unit of Britain's Meggitt Plc (MGGT.L).

"Our investigators are moving swiftly and we are making progress," Kelly Nantel, a spokeswoman for the U.S. National Transportation Safety Board, said after the U.S. safety board issued a seventh update on the investigation. She did not elaborate.

Boeing welcomed the news and said it continued to work closely with authorities in the United States and Japan.

The NTSB said an expert from the Department of Energy had joined the investigation, and an NTSB investigator would travel to France on Sunday or Monday with a "battery contactor", which connects the battery to the planes' electrical systems, for further tests at the equipment's manufacturer, Thales SA (TCFP.PA).

The NTSB experts at the U.S. Naval Surface Warfare Center laboratories were continuing to look at a second, undamaged lithium-ion battery pulled from the same Japan Airlines (9201.T) plane. Both batteries were built by GS Yuasa (6674.T), a Japanese company.

Initial tests, including infrared thermal imaging of each cell in the undamaged battery, found no anomalies, according to the NTSB update. It said the battery's eight cells were undergoing another scan to examine their internal condition.

U.S., Japanese and French safety inspectors - aided by industry officials - have been trying to determine what caused the battery fire on the 787 in Boston and a separate battery failure in Japan that involved smoke the following week.

The failure of investigators to identify the root cause of the incidents has sparked concerns that the 787 grounding will last longer, and hit Boeing and the airlines that operate the 787 harder than expected.

But Boeing's chief executive, Jim McNerney, told investors this week that the company planned to speed up production of the jet as planned, and had not seen any reason to question its use of lithium ion batteries on the 787.

Boeing's shares closed 1.35 percent higher at $74.87 on the New York Stock Exchange on Tuesday.

Neither the NTSB, nor the U.S. Federal Aviation Administration, which is looking at a broader range of problems with the 787, have set timetables for completing their work.

Investigations are also continuing in Seattle, where Boeing builds the planes, and in Japan. (Reporting By Andrea Shalal-Esa; Editing by Leslie Gevirtz and Carol Bishopric).

On a sameday, ABU DHABI's Reuthers shows that Etihad Airways which the slogan is Abu Dhabi to the World, Chief Executive Officer. Mr. James Hogan has no doubt about the 787 overcome soon and said it is great planes and no plan to cancelling. Etihad Airways ordered 41 planes of 787-9, 25 option, which the passanger choices TBA, and delivery will be 2014 and 2019.

Valued at a combined $2.8 billion at current list prices (2011), this order made Etihad the world's largest airline customer of the 787-9. Etihad has a total of 41 787s on order.

The order also increased Etihad's current Boeing 777 backlog to 12 airplanes, which includes 10 previously ordered 777-300ERs (extended range). The Abu Dhabi-based airline's fleet currently includes eight Boeing 777-300ERs and one 777 Freighter.

"Our decision to expand our Dreamliner fleet is testimony to Etihad's commitment to operating one of the youngest and most fuel efficient fleets in the skies," said Etihad Airways Chief Executive Officer, Mr. James Hogan. "It also reflects our confidence in the 787's ability to have a significant impact on our operating efficiencies and the passenger experience we can offer onboard this revolutionary aircraft. Both the Boeing 787 Dreamliner and the 777 Freighter offer highly attractive operating economics and will facilitate our global expansion plans by allowing us to transport passengers and cargo into new global markets from our hub in Abu Dhabi."

Etihad Airways announced what was the largest aircraft order in commercial aviation history at the Farnborough Airshow in 2008, for up to 205 aircraft – 100 firm orders, 55 options and 50 purchase rights. As of January 2012, the airline operates passenger and cargo services to 85 destinations around the world from its home base in Abu Dhabi. In 2011, Etihad carried 8.3 million passengers, a 17% increase on the previous year, delivering revenues of US$ 4.1 billion and net profits of US$ 14 million.

787 manufacturing and supply teams spent years applying a rigorous and disciplined approach to ensure the Dreamliner set new standards in performance, efficiency and safety. The Boeing team conducted the most comprehensive testing and certification efforts in history on this program and according to the Boeing, safety is the first priority for the customers to fly. The Boeing 787 investigations continue to making progress. Meanwhile, same date, February 4th, 2013, Puget Sound Business Journal shows that FAA may allow Boeing to fly 787s for battery tests Boeing has asked the Federal Aviation Administration for permission to conduct test flights of the 787 Dreamliner to gather more information to help solve the aircraft’s battery problems, the company confirmed. The request for the test flights is “currently under evaluation by the FAA,” said Boeing spokesman Scott Lefeber, in an email. A source at the FAA also confirmed the Boeing request. The Boeing 787 Dreamliner soon to be overcome like all of us and many are having expectation, in time service of FAA with an economical and quality - reliable service which they have been in many ways......

|

|

Sources:Boeing, yahoo, wikipedia Reuthers, Puget Sound Business Journal, and NTSB R\catch4all.com, Sandra Englund February 4th, 2013. |

Boeing: February 2nd, 2013

|

||

|

With an almost centennial near in 2016 and with the dynamic team about, 170,000 Boeing employees from around the world, its suppliers, and when needed, external experts in specialized fields., the Boeing continues to developing the world’s safest, most advanced commercial aviation products. And when the company needs to focus, it does so with passion, diligence and precision. The Dreamliner 787 is no difference, 787 manufacturing and supply teams spent years applying a rigorous and disciplined approach to ensure the Dreamliner set new standards in performance, efficiency and safety. The Boeing team conducted the most comprehensive testing and certification efforts in history on this program. In January 2013, Boeing responds promptly, the Dreamliner experienced two incidents (one in the U.S. and the other in Japan) involving the main and auxiliary power unit (APU) battery that has led to customer, regulatory and investigative action. Boeing is marshaling its vast resources to understand the cause of these events. 787 engineering team began a detailed analysis of messages sent from the airplane to the company’s 24-hour monitoring center in Everett, Wash. As details emerged, experts from around the company convened to review relevant systems. In the earliest hours, program teams mobilized to provide support on a number of fronts. Crews were immediately dispatched to the site of the events in the U.S. and Japan to support the investigations as requested by authorities. As the teams better understand the situation and the investigation narrows, additional teams of experts will be asked to assist. Boeing has formed teams consisting of hundreds of engineering and technical experts who are working around the clock to understand the recent 787 incidents and define the actions necessary to get the airplane back to flight status. With making every possible as much finding for better improvement since January 7, 2013, Dreamliner experienced two incidents (one in the U.S. and the other in Japan) involving the main and auxiliary power unit (APU) battery that has led to customer, regulatory and investigative action. Boeing is marshaling its vast resources to understand the cause of these events, soon will be overcome which will be ready for the best and the most safest airplane for the customers like the Iron Age, blacksmith metallurgists have known that metals such as steel become stronger and harder the more you hit (or beat) on them which applies the theory of dislocation was invented in the 1930s. Research since then has focused on dislocation interactions and their role in hardening metals, in which continued deformation increases the metal’s strength (much like a blacksmith pounding on steel with an anvil). The Boeing Commercial 787, a long-range, mid-size wide-body, twin-engine jet airliner which it variants seat 210 to 290 passengers. it is known to be the most fuel-efficient airliner and the world's first major airliner to use composite materials as the primary material in the construction of its airframe which is 20% more fuel efficient than the 767 it is to replace and features include mostly electrical flight systems, a four-panel windshield, noise-reducing chevrons on its engine nacelles, and a smoother nose contour. It shares a common type rating with the larger 777 twinjet, allowing qualified pilots to operate both models, due to related design features has been designed to be 20% more fuel efficient than the 767 it is to replace. It shares a common type rating with the larger 777 twinjet, allowing qualified pilots to operate both models, due to related design features. Meanwhile, AOPA and ALEA action has been taken for the NTSB safety recommendations with the following: |

||

|

||

|

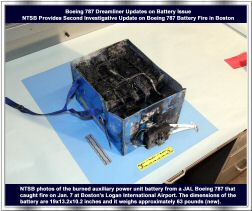

NTSB: NTSB Press Release: National Transportation Safety Board Office of Public Affairs, dated February 1st, 2013, The seventh updated investigation report was released by The National Transportation Safety Board on February, 1st, 2013 which was on its investigation into the Jan. 7 fire aboard a Japan Airlines Boeing 787 at Logan International Airport in Boston. The auxiliary power unit battery, manufactured by GS Yuasa, was the original battery delivered with the airplane on December 20, 2012. It is comprised of eight individual cells. All eight cells came from the same manufacturing lot in July 2012. The battery was assembled in September 2012 and installed on the aircraft on October 15, 2012. It was first charged on October 19, 2012. Examination and testing of an exemplar battery got underway earlier this week at the Carderock Division of the Naval Surface Warfare Center laboratories in West Bethesda, MD. The tests consisted of electrical measurements, mass measurements, and infrared thermal imaging of each cell, with no anomalies noted. The cells are currently undergoing CT scanning to examine their internal condition. In addition, on Thursday, a battery expert from the Department of Energy joined the investigative team to lend his expertise to the ongoing testing and validation work. NTSB investigators were made aware of reports of prior battery replacements on aircraft in the 787 fleet, early in the investigation. As reported Tuesday, Boeing, a party to the investigation, is providing pertinent fleet information which investigators will review to determine if there is any relevance to the JAL investigation.

An investigative group continued to interpret data from the two digital flight data recorders on the aircraft, and is examining recorded signals to determine if they might yield additional information about the performance of the battery and the operation of the charging system. Next week, the NTSB battery testing team will initiate a non-invasive "soft short" test of all cells of the exemplar battery. This test will reveal the presence of any high resistance, small or "soft" shorts within a cell. Also, an NTSB investigator will travel to France with the battery contactor from the JAL event battery, for examination at the manufacturer. The battery contactor connects a wiring bundle from the airplane to the battery. Investigators are continuing their work in Washington and Japan and the team in Seattle continues to observe the FAA-led review of the certification process for the 787 battery system. The flow of information from these observations helps to inform NTSB investigative activity in the US and around the world. Additional information on the NTSB's investigation of the Japan Airlines B-787 battery fire in Boston is available at http://go.usa.gov/4K4J. The NTSB will provide another factual update as developments warrant. To be alerted to any updates or developments, follow the NTSB on Twitter at www.twitter.com/ntsb. NTSB Media Contact: ---------------------------------------- Since NTSB investigators was looking into Boeing 787 smoke event in Boston on January 7th, 2013 which NTSB Investigators with the National Transportation Safety Board. The NTSB has dispatched an investigator to Boston. Based on a review of the factual information gathered, the NTSB has determining the extent of its investigation. Meanwhile, Chairman Deborah A.P. Hersman was giving briefings about the JAL Boeing 787 battery fire investigation on preliminary findings regarding the JAL Boeing 787 battery fire investigation and detailed information was given on January 24, 2013, and the serious investigation has been continued between the NTSB and the Boeing which Investigators are continuing their work in Washington and Japan and the team in Seattle continues to observe the FAA-led review of the certification process for the 787 battery system. The flow of information from these observations helps to inform NTSB investigative activity in the US and around the world which is the safety of passengers and crew members who fly aboard Boeing airplanes is the highest priority, no matter what how long it will takes.....meanwhile the quality and the systemetical protocol will help in time service for a long term service and it will make safe fly anywhere, anyplace, anytime, no matter what howlong will take to fly........

|

||

|

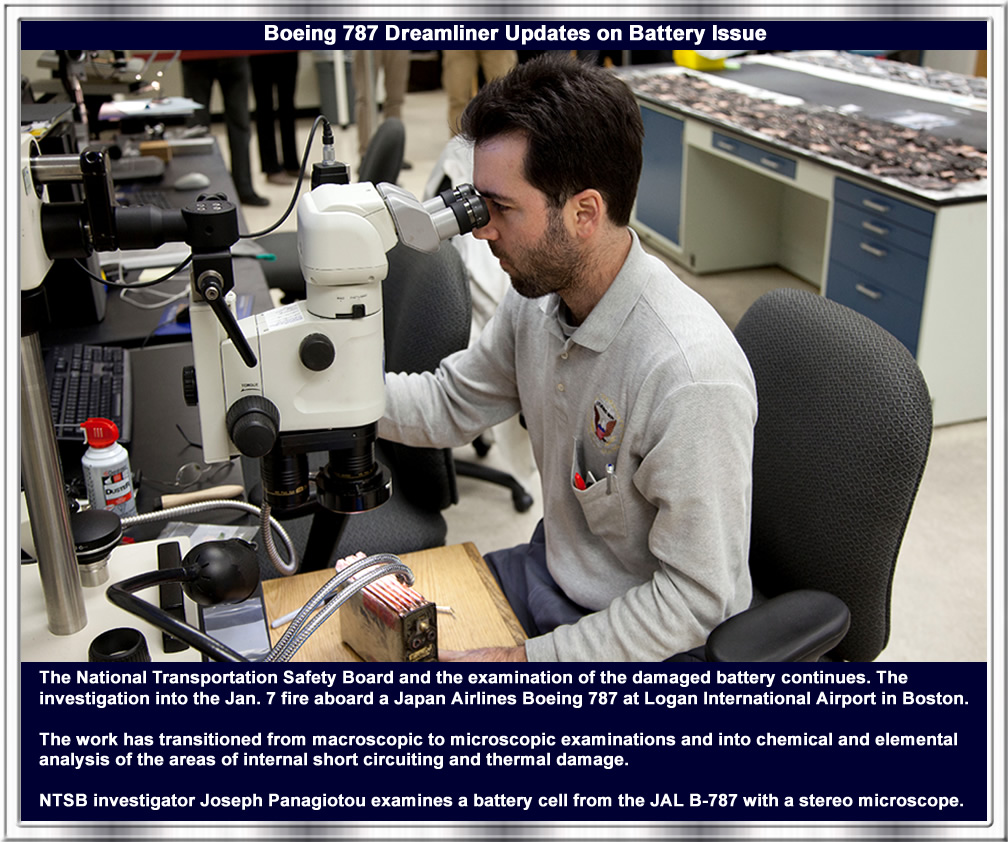

NTSB: January 29th, 2013 According to the NTSB Press Release dated January 29th, 2013: The National Transportation Safety Board today released the sixth update on its investigation into the Jan. 7 fire aboard a Japan Airlines Boeing 787 at Logan International Airport in Boston. The examination of the damaged battery continues. The work has transitioned from macroscopic to microscopic examinations and into chemical and elemental analysis of the areas of internal short circuiting and thermal damage. The following is from NTSB investigator Joseph Panagiotou examines a battery cell from the JAL B-787 with a stereo microscope:

Examination and testing of the exemplar battery from the JAL airplane has begun at the Carderock Division of the Naval Surface Warfare Center laboratories. Detailed examinations will be looking for signs of in-service damage and manufacturing defects. The test program will include mechanical and electrical tests to determine the performance of the battery, and to uncover signs of any degradation in expected performance. As a party contributing to the investigation, Boeing is providing pertinent fleet information, which will help investigators understand the operating history of lithium-ion batteries on those airplanes. An investigative group continued to interpret data from the two digital flight data recorders on the aircraft, and is examining recorded signals to determine if they might yield additional information about the performance of the battery and the operation of the charging system. In addition to the activities in Washington, investigators are continuing their work in Seattle and Japan. Additional information on the NTSB's investigation of the Japan Airlines B-787 battery fire in Boston is available at http://go.usa.gov/4K4J. The NTSB will provide another factual update on Friday, Feb. 1, or earlier if developments warrant. To be alerted to any updates or developments, follow the NTSB on Twitter at www.twitter.com/ntsb. NTSB Media Contact:Office of Public Affairs 490 L'Enfant Plaza, SW Washington, DC 20594 (202) 314-6100 Peter Knudson peter.knudson@ntsb.gov ------------------------------- Boeing 787 Dreamliner JAL Battery Fire JA829J which the First flight was on July 12th, 2012 and Construction Number (MSN) is 34839 which is line number 84 and air frame was active. JA829J delivered to Japan Airline on December 21st, 2012. Boeing continues to assist the NTSB and the other government agencies in the U.S. and Japan responsible for investigating two recent 787 incidents. The company has formed teams consisting of hundreds of engineering and technical experts who are working around the clock with the sole focus of resolving the issue and returning the 787 fleet to flight status. We are working this issue tirelessly in cooperation with our customers and the appropriate regulatory and investigative authorities. The safety of passengers and crew members who fly aboard Boeing airplanes is our highest priority.

|

|

Boeing 787 Dreamliner Updates on Battery Issue January 24th, 2013 SEATTLE, Jan. 24, 2013 /PRNewswire/ -- Boeing (NYSE: BA) welcomes the progress being made in the 787 investigation discussed today by the U.S. National Transportation Safety Board (NTSB) in Washington, D.C. The regulatory and investigative agencies in the U.S. and Japan have dedicated substantial resources to these investigations, and we appreciate their effort and leadership. Boeing continues to assist the NTSB and the other government agencies in the U.S. and Japan responsible for investigating two recent 787 incidents. The company has formed teams consisting of hundreds of engineering and technical experts who are working around the clock with the sole focus of resolving the issue and returning the 787 fleet to flight status. We are working this issue tirelessly in cooperation with our customers and the appropriate regulatory and investigative authorities. The safety of passengers and crew members who fly aboard Boeing airplanes is our highest priority. In order to ensure the integrity of the process and in adherence to international protocols that govern safety investigations, we are not permitted to comment directly on the ongoing investigations. Boeing is eager to see both investigative groups continue their work and determine the cause of these events, and we support their thorough resolution. Boeing deeply regrets the impact that recent events have had on the operating schedules of our customers and their passengers. Contact: SOURCE Boeing ------------------------------------------------------------------------------ |

||||||

|

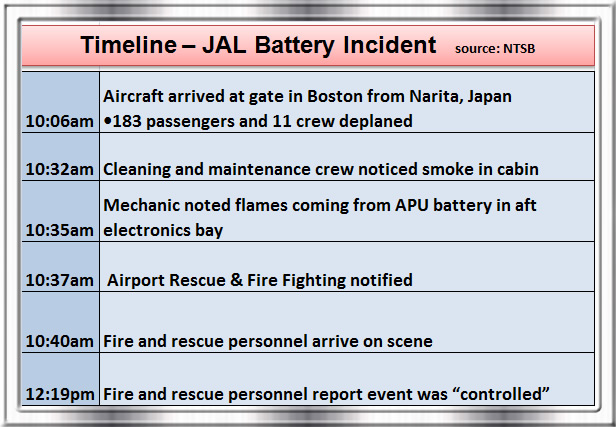

According to Press release from NTSB In a press conference January 24th, 2013, National Transportation Safety Board Chairman Deborah A.P. Hersman released preliminary findings from the NTSB's ongoing investigation into the Jan. 7, 2013, Boeing 787 battery fire in Boston. "We have not ruled anything out as a potential factor in the battery fire; there are still many questions to be answered," Hersman said. Noting that there was a B-787 battery incident in Japan on Jan. 16, 2013, which is being investigated by the Japan Transport Safety Board, Hersman said, "One of these events alone is serious; two of them in close proximity, especially in an airplane model with only about 100,000 flight hours, underscores the importance of getting to the root cause of these incidents." The investigation revealed that the battery in the B-787 fire in Boston showed signs of short circuiting, and had indications of thermal runaway, a situation in which a significant temperature increase can initiate a destructive chain reaction. Chairman Hersman also expressed concerns about the adequacy of the systems to prevent such a fire from occurring. "The investigation will include an evaluation of how a fault that resulted in a battery fire could have defeated the safeguards in place to guard against that," said Hersman. "As we learn more in this investigation, we will make recommendations for needed improvements to prevent a recurrence." NTSB timeline of the events on Jan. 7, which was released on January 24th, 2013 during their press release:

The batteries were manufactured by GS Yuasa for the Thales electrical installation and are unique to the Boeing 787. The same battery model is used for the main airplane battery and for the battery that is used to start the auxiliary power unit, which is the one that caught fire in Boston. Thales Group is a French multinational company that designs and builds electrical systems.Thales Group is a French multinational company that designs and builds electrical systems. You can see the before and after the accident for the Batteries:

Radiographic examinations of the incident battery and an exemplar battery were conducted at an independent test facility. The digital radiographs, or computed tomography (CT) scans, generated from these examinations allowed NTSB investigators to document the internal condition of the battery prior to disassembling it. Ongoing lab work includes an examination of the battery elements with a scanning-electron microscope and energy-dispersive spectroscopy to analyze the elemental constituents of the electrodes to identify contaminants or defects. NTSB INVESTIGATIVE TEAMS In addition to the activities at the NTSB lab in Washington, members of the investigative team have been conducting work in Arizona, Seattle and Japan. Their activities are detailed below. ARIZONA SEATTLE JAPAN You will be able to see more detail via video by NTSB: The Boeing highest priority is for The safety of passengers and crew members who fly aboard Boeing airplanes. In order to ensure the integrity of the process and in adherence to international protocols that govern safety investigations, The Boeing permitted to comment directly on the ongoing investigations. Boeing is eager to see both investigative groups continue their work and determine the cause of these events, and Boeing is committed and to support their thorough resolution. Boeing deeply regrets the impact that recent events have had on the operating schedules of customers and their passengers meanwhile Boeing is continues to making the most safety is their first priority for the customers.

|

Boeing 787 Dreamliner Updates on Battery Issue

Boeing engineer says confident 787 safe,

no comment on probe length

Boeing Statement on Federal Aviation Administration 787 Action

|

Boeing is

confident the 787 is safe and stand behind its overall integrity. Boeing will

be taking every necessary step in the coming days to assure the customers and

the traveling public of the 787's safety and to return the airplanes to

service. FAA Federal

Aviation Administration, made press release FAA Statement due to the Boeing

787 battery incident earlier in Japan, the FAA is taking action issued an

emergency airworthiness directive (AD) to address a potential battery fire risk

in the 787 and require operators to temporarily cease operations. Before

further flight, operators of U.S.-registered, Boeing 787 aircraft must

demonstrate to the Federal Aviation Administration (FAA) that the batteries are

safe. FAA stated

that The in-flight Japanese battery incident followed an earlier 787 battery

incident that occurred on the ground in Boston on January 7, 2013. The AD is

prompted by this second incident involving a lithium ion battery. The battery

failures resulted in release of flammable electrolytes, heat damage, and smoke

on two Model 787 airplanes. The root cause of these failures is currently under

investigation. These conditions, if not corrected, could result in damage to

critical systems and structures, and the potential for fire in the electrical

compartment. Last Friday,

the FAA announced a comprehensive review of the 787’s critical systems with the

possibility of further action pending new data and information. In addition to

the continuing review of the aircraft’s design, manufacture and assembly, the

agency also will validate that 787 batteries and the battery system on the

aircraft are in compliance with the special condition the agency issued as part

of the aircraft’s certification. United

Airlines is currently the only U.S. airline operating the 787, with six

airplanes in service. When the FAA issues an airworthiness directive, it also

alerts the international aviation community to the action so other civil

aviation authorities can take parallel action to cover the fleets operating in